The MIRA Large Sample Room Scanning Electron Microscope (LC-SEM) from Germany has been widely used in aviation, aerospace, semiconductor industry, automotive manufacturing, wind power equipment, materials science, and other industries due to its unique characteristics of a large sample room since its launch. LC-SEM can be equipped with multiple detection devices (backscattered electron detector, SE, EDS, EBSD, FIB, FT-IR) simultaneously to meet different needs. Not only can it inspect the physical properties of large components, but it can also evaluate the chemical and crystalline properties of raw materials. Almost accurate results can be achieved for any sample, up to a one-stop inspection and analysis at the molecular level.

In situ testing solution

Large sample room scanning electron microscope

Product overview

产品特点

PRODUCTFEATURE

Having the functions and characteristics of a regular SEM

The sample room can accommodate large samples for non-destructive testing of samples

Mobile electronic optics and detectors with a wide field of view for observation

Provide multiple detectors and testing functions; EDS、EBSD、 Stretching, creep, fatigue, etc.

Further development of testing functions and applications is possible

应用案例

PRODUCTSCENARIO

Semiconductor Industry - Analysis of Wafer Chuck

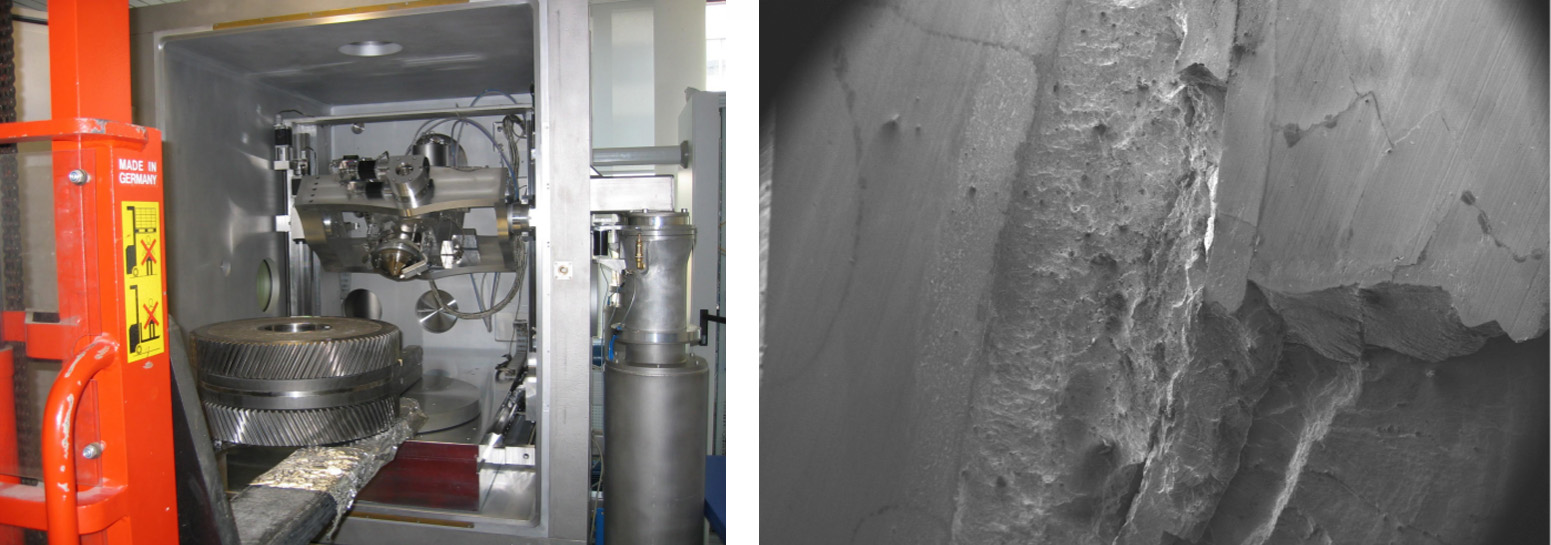

Perform failure analysis on the cross-section of the worn area of the tire section

Test results for wind turbines

产品规格

PRODUCTPARAMETER

| Resolution ratio | Better than 10nm |

| Magnification | 10x~300000x |

| Electron beam acceleration voltage | 0.2~30keV |

| Detector | Secondary reflection channel doubling electron detector; Four quadrant backscattered electron detector |

| Analytical ability | Energy dispersive X-ray spectrometer (EDS); Electron backscatter diffractometer (EBSD) |

| Additional functions | Focused ion beam (FIB); Fourier transform infrared spectrometer (FT-IR); Internal camera system |

| Software | MIRA control system |

| Hardware | Computers, monitors, and printers |

| Low vacuum pump | Mechanical pump, 65m ³/h; Roots pump, 400m ³/h |

| High vacuum pump | Molecular pump 2400L/s |

| Ultimate Pressure | After 45 minutes, 10 ⁻⁶ mabr |

| Vacuum chamber | 3 m³; 9 m³; 12 m³ |

| Motor System | 5+1 Microstep Control Axis System |

| Repeat accuracy | ±50 μm |

| Sample maximum size | Diameter 1500mm, height 1500mm |

| Maximum mass | 300 kg |

| I. Electronic optical system | |

| Electron gun | Electronic optical system |

| SE resolution | Better than 10nm |

| Accelerating voltage | 200V to 30kV, continuously adjustable |

| Magnification factor | 10 times to 300,000 times |

| Detector | |

| Secondary reflection channel multiplier electron detector Quadrant back - scattered electron detector | |

| Energy - dispersive X - ray spectrometer (EDS) Electron back - scattered diffraction apparatus (EBSD) | |

| III. Additional functions | |

| Focused Ion Beam (FIB) | |

| Fourier Transform Infrared Spectrometer (FT - IR) | |

| Internal camera system | |

| IV. Image processing | |

| Software | MIRA control system |

| Hardware | Computers, monitors and printers |

| V. Vacuum system | |

| Low vacuum pump | Mechanical pump, with a flow rate of 65 cubic meters per hour; Roots pump, with a flow rate of 400 cubic meters per hour. |

| High - vacuum pump | Molecular pump, with a pumping speed of 2400 liters per second. |

| Ultimate vacuum | 10 to the power of minus 6 millibar after 45 minutes. |

| Vacuum chamber | 3m³;9m³;12m³ |

| VI. Positioning system | |

| Motion system | 5 + 1 micro - step control axis system |

| Repeatability accuracy | ±50μm |

| VII. Positioning range | |

| X - axis | 600mm,1000mm,1500mm |

| Z - axis | 600mm,1000mm,1500mm |

| A - axis | 90° |

| B - axis | 135° |

| C - axis | 360° |

| D - axis | 350° |

| VIII. Samples | |

| Maximum size | Diameter: 1500 millimeters, Height: 1500 millimeters |

| Maximum Mass | 300 kg |